Applications

What is Corrosion Testing?

Corrosion Testing is widely know or referred to as “Salt Spray Testing”, “Salt Fog Testing” or “Cyclic Corrosion Testing” (CCT). There are corporate test methods form the Automotive Industry and Aerospace Industry and National and International Standards written, which detail the methods of Corrosion Testing.

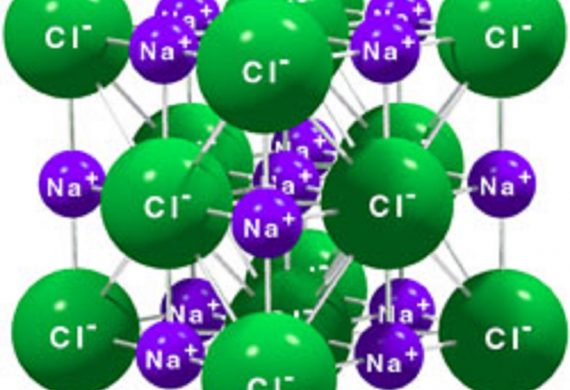

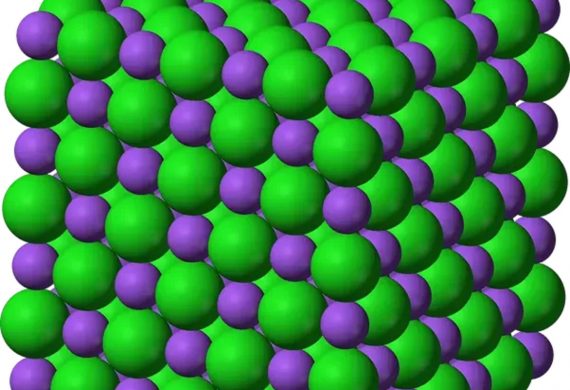

All these Standards and Test Methods specify that Sodium Chloride or common salt should be used in a pure form.

The Corrosion Testing involves spraying a solution of Sodium Chloride at a component or protective or decorative coating to accelerate the breakdown, degradation or failure of the component or coating.

Other tests involve the immersion of products in tanks of salt water which also show how a product resists corrosion.

Why is salt used?

Salt is one of the most commonly occurring compounds in the world, as it mostly responsible for the salinity of sea water and it is widely used for de-icing the roadways in sub-freezing weather. When in a solution it is highly corrosive.

What Salt to Use

Most Sodium Chloride found around the world contains impurities and trace elements and today salt used for Corrosion Testing must have very low levels of some specific trace elements. The majority of salt commercially available today contains anti-caking agents, which are added to the salt to keep it in a free flowing granular format.

Salt found to contain these agents cannot be used for Corrosion Testing.

Anti-caking agents are also know as Potassium or Sodium Ferrocyanide or Potassium Hexacynoferrate II or chemically as K4Fe (CN)6.

-

The salt cannot contain any anti-caking agent.

-

Halides (Bromide, Fluoride & Iodine only) < 0.1%.

-

The total impurities < = 0.3%.

-

Copper < 0.3ppm.